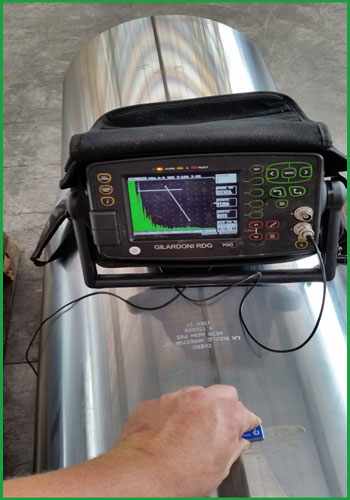

Eddy current testing a modern Non-destructive testing – NDT method that has become one of the prime tool for quality control of products, materials and structures at various stages of manufacturing and in-service inspections. Eddy current inspection can be used to find finest surface and subsurface flaws in any conductive material. Spectrums of quality control engineering applications are existing applying Eddy current principles. Present Eddy current NDT method has applications in Aerospace Component Inspections, Heat exchanger tube inspections and other critical engineering applications.

We at 'Valour Alloys Inc.' provide reliable and dependable services on Eddy current testing fine tuned to the client needs with our expert team of NDT Level II, III professionals and state of art equipment's & approved NDT testing procedures that meets national and international standards. We can perform Eddy current inspection both in-house and onsite inspections. Contact Valour Alloys Inc. for more information on your NDT inspection, training and certification, welding inspection and other quality control needs.